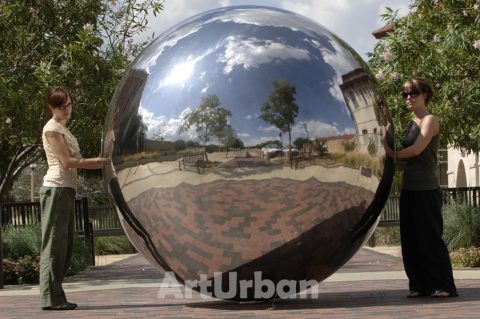

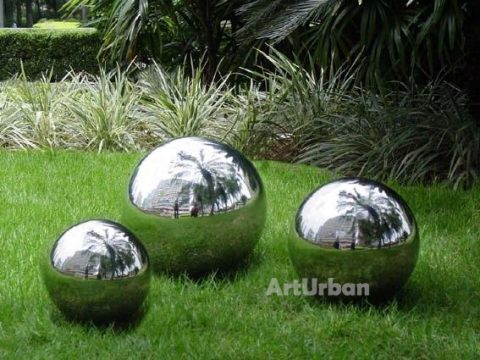

Item No: ARTBXG-001

Size: 50-150 cm in diameter , or custom as your requirement

Wall Thickness: 2-3mm (can be adjusted depends on the size of sculpture)

Producing Time: About 30-50 days after receiving your order

Material: Stainless Steel:#304#201#316r

Design: We also supply custom-made service based our cusotmers' requests

Package: Strong wooden crate with waterproof and shockproof foam inside

Stainless Steel Sphere Sculpture production process

Mirror polished stainless steel sculptures are widely used in modern public art due to their stunning finishes and beautiful artistic appearance. However, as we all know, it is not easy to make perfect mirror polished stainless steel sculptures. In this announcement, the sculpture manufacturer will introduce the complete production process of stainless steel sculpture. Mirror polished stainless steel sculpture Below is a brief description of how we made it.

Step 1: Digital Modeling of Stainless Steel Sculpture

The commonly used digital model applications are Zbrush, 3DMax, Rhino C4D and other 3D design software. Digital Modeling of Stainless Steel Sculpture

Step 2: Engineering and prefabricated stainless steel plates

High-quality Kexiu Steel is the foundation for exquisite works. We use marine grade stainless steel plate 316, which has excellent corrosion resistance and high strength. It must be ensured that stainless steel sculptures will never corrode outdoors, even in warm and high humidity environments. Compared with stainless steel 201 and 304, stainless steel 316 has better manufacturing quality.

Mirror polished stainless steel sculpture

The armature and base of the sculpture are 16 mm thick and the structure is very strong. It can even allow several adults to climb onto the sculpture. Cut and dome the stainless steel plate according to the design. We use a high-precision water jet or plasma cutting machine to cut the stainless steel plate into the shape we want.

Step 3: Welding the skeleton of the stainless steel sculpture

All connectors have been fully connected to maximize the use of TIG and MIG for soldering. The bar must be exactly the same as the stainless steel plate. Otherwise, there will be imperfections in the finished product. Mirror polished stainless steel sculpture welding

Step 4: Making stainless steel sculpture

This is a critical step in the entire manufacturing process. Only experienced manufacturers are allocated in the fine stage. The sculpture will be formed as its design. All welded joints and seams must be inspected. We carefully check the angle of the sculpture to make sure it is correct. In theory, as long as the welded sculpture skeleton is correct, it should be correct. However, careful measurement is important during the manufacturing process. This can ensure the accuracy of stainless steel sculpture production. We lifted the sculpture to check its overall appearance. looks good.

Step 5: Polishing the stainless steel sculpture

Polishing is a dirty job, involving many steps. The polishing craftsman must have superb polishing skills. These are commonly used polishing materials: polishing cotton wheels, non-woven fabrics. The hard polishing wheel of the polishing paste is used in the first stage, and then it is finished with a softer cotton wheel. Different colors are also used in different stages. Stainless steel sculpture polishing

Step 6 transportation and installation

Stainless steel sculpture installation is the last link of the entire project process. Generally, large stainless steel sculptures will have a base. If it is a relatively small stainless steel sculpture, the embedded parts must be made and then buried in the ground.

We can custom the stainless steel sphere sculpture, metal garden sculptures for sale in any size as you want.

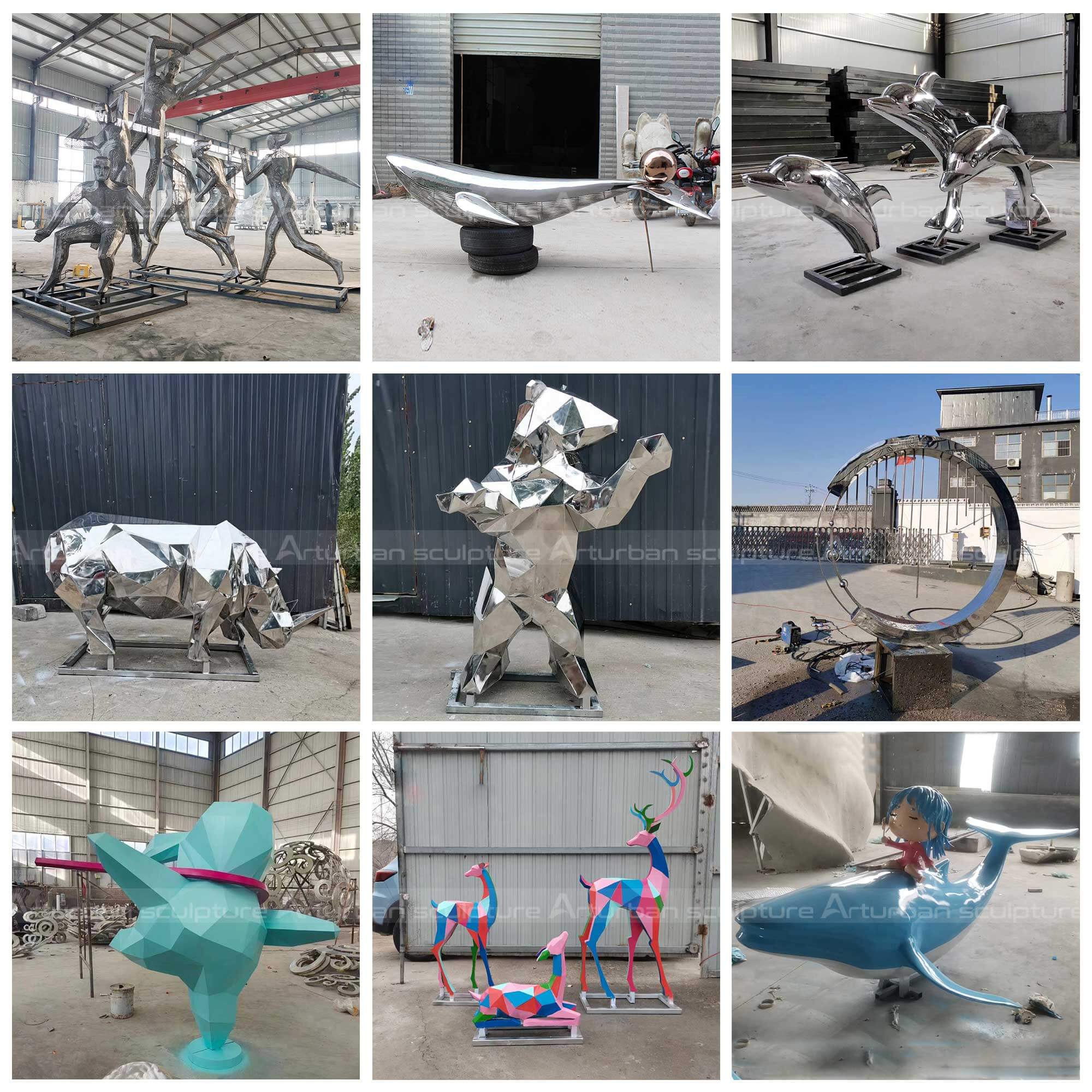

2. Project cases of stainless steel sculpture